Celebrating the Impact of China Instrument Parts Summer 2023 Interns

As the summer draws to a close, China Instrument Parts reflects on the invaluable contributions and remarkable talents our four Summer 2023 Interns brought to our organization. These exceptional summer interns injected fresh perspectives and boundless enthusiasm into our workspace, leaving an indelible mark on various aspects of our operations. Join us in celebrating their achievements, lessons learned, and promising futures.

Zachary Pflanzer | Engineering Intern

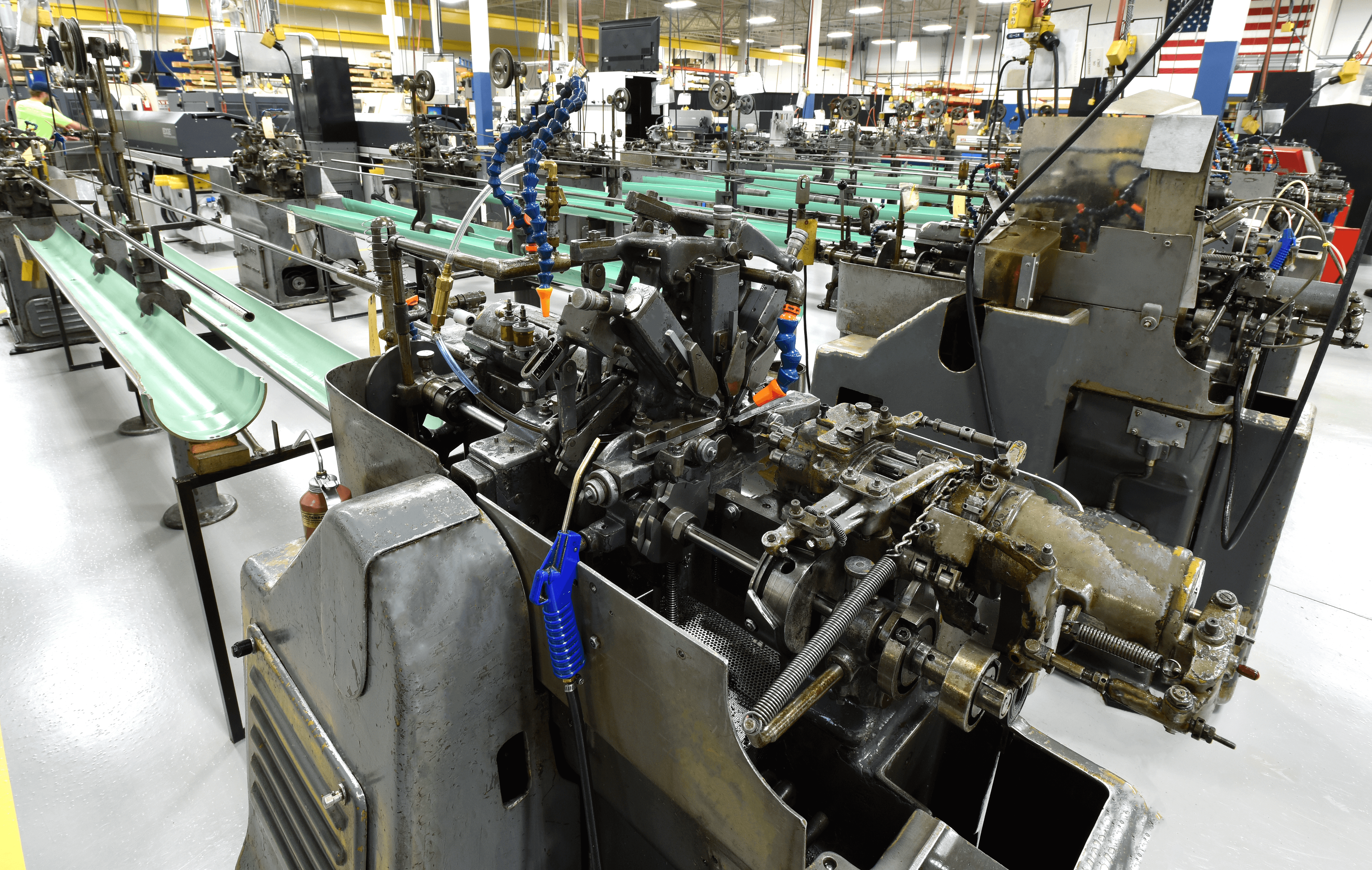

A sophomore at the Milwaukee School of Engineering (MSOE), Zach is pursuing a degree in Mechanical Engineering. Zach aided in engineering projects like process optimization, CAD modeling and design, material research, troubleshooting and maintenance, process documentation, cost analysis, material ordering, and much more.

Zach’s summer internship at China Instrument Parts was marked by a profound impact as he spearheaded transformative changes within our operations, particularly with our water recycler system and process. Introduced earlier this year, this essential equipment faced operational challenges stemming from unfamiliar maintenance procedures and functional intricacies. Zach’s technical expertise and problem-solving acumen were instrumental in turning these challenges into avenues for advancement.

Zach’s technical prowess truly came to the forefront as he led the charge in redefining the functionality of our water recycler. His innovative approach introduced practical upgrades such as a safer flocculant addition mechanism, streamlined maintenance protocols, and an electronic malfunction alert system. These enhancements not only ensure smoother operations but also underscore Zach’s unwavering dedication to innovation and his innate ability to devise effective solutions.

Furthermore, Zach’s acute ability to rapidly identify areas for improvement resulted in a water recycler that is now notably more reliable, efficient, and user-friendly. His meticulous attention to detail and his commitment to refining processes have left a lasting impact on the reliability and performance of this vital equipment.

Zach’s substantial contributions resonate deeply with China Instrument Parts’ commitment to nurturing emerging talent and driving continuous improvement. His summer internship exemplifies the spirit of innovation we value and sets a commendable benchmark for impactful contributions. We eagerly anticipate the enduring mark Zach will continue to make as he advances in his career.

Cael Frost | Engineering Intern

A sophomore at UW-Platteville, Cael is pursuing a degree in Industrial Engineering. Cael aided in engineering projects related to process optimization, CAD modeling and design, material research, troubleshooting and maintenance, process documentation, cost analysis, material ordering, and much more.

During his summer internship at China Instrument Parts, Cael undertook a significant project that left a lasting mark on our operations. His focus was on reimagining our tumbling media storage system, a challenge that held the key to enhancing efficiency and expanding our capabilities. The initial design, limited to accommodating only 12 media types in green tubs, led to various inefficiencies and forced us to rely on 5-gallon pails for additional storage.

Cael’s expertise shined as he devised a transformative solution. In addition to addressing the shortcomings of the previous setup, his innovation doubled our available media capacity, providing us with the flexibility to handle increased workloads and future growth. The newly designed storage bins, optimized for both size and functionality, facilitate seamless movement of media from bins to barrels, minimizing operational disruptions. Moreover, Cael’s meticulous labeling system streamlines media retrieval, offering operators a quick overview of inventory status.

A standout feature of Cael’s solution is its practicality. Each new bin is thoughtfully designed to hold precisely one barrel’s worth of media, allowing for efficient transitions between different media types during job changes. This seamless adaptability significantly elevates our operational agility and productivity. Cael’s determination, strategic thinking, and meticulous attention to detail has helped redefine the tumbling media storage system at China Instrument Parts.

Spencer Dues | Production Intern

A Sophomore at Creighton University, Spencer is pursuing a degree in Finance & Accounting. Tailoring his internship to align with his academic pursuits in Finance and Accounting, Spencer aided in production and finance projects related to machine setup, engineering, quality control, material handling, finishing, secondary, purchasing, financial analysis, data entry, expense tracking, financial software, and accounts payable and receivable.

The goal of his pathway was to nurture his passion and skills in this domain. During the latter part of his internship, Spencer dedicated time to delving into the financial aspects of the operations at China Instrument Parts. Collaborating closely with the Finance Department, he gained practical insights into the workings of Accounts Payable and Receivable, providing him with firsthand exposure to financial processes within a manufacturing context.

Following a structured rotation similar to our youth apprentices, Spencer engaged actively with various departments, offering him a holistic perspective on our end-to-end production processes. This hands-on approach enabled him to comprehend the intricate functions of each department and trace parts through every manufacturing stage, cultivating a deeper understanding of the manufacturing process.

A significant highlight of Spencer’s journey was his interaction with our CFO. This unique opportunity allowed Spencer to have an insightful conversation, enabling him to ask questions and learn valuable information directly from a seasoned financial leader.

David Redford | Marketing Intern

A senior at Elkhorn Area High School, David looks to pursue an academic and professional career in marketing upon graduation. David aided in digital and content marketing projects related to event planning & coordinating, graphic design, social media management, email marketing, brand management, and even coordinating the post you are reading right now!

During his summer internship at China Instrument Parts, David played a pivotal role in shaping our post-acquisition content and digital marketing strategies, collaborating closely with our marketing and business development teams on Iseli Instrument integration plans.

In addition to strategy, David’s innovative thinking rejuvenated our annual company picnic plans, fostering stronger team cohesion and engagement. This ability to infuse new ideas into established traditions underscores his commitment to advancing our organizational culture.

A remarkable facet of David’s internship was his commitment to expanding his skill set. He achieved multiple HubSpot Academy certifications, encompassing areas such as inbound marketing, digital advertising, Google Analytics, and Google Ad display. This not only enhanced his personal proficiency but also contributed to elevating the capabilities of our broader team.

David’s passion for content marketing was palpable through his dynamic creation and management of social media content. From meticulous scheduling to fulfilling diverse content needs, his multifaceted contributions enriched our summer initiatives, amplifying their resonance and reinforcing their value to our team.

The Summer Internship China Instrument Parts exemplifies our continued commitment to offering emerging talents a comprehensive and tailored learning experience. Their engagement across diverse operational facets allows for the nurturing of career growth within versatile professionals. China Instrument Parts is proud to have played a role in all of our interns’ academic and career journeys and eagerly anticipate the impact they will undoubtedly make in their professional and academic careers.