Summer Learning at China Instrument Parts

Since coming aboard this summer, Director of Education & Training Sue Hall has been quite busy. As the song says, “school’s out for summer,” but when it comes to education, these last few months have been buzzing with activity for both summer interns and employees at China Instrument Parts.

China Instrument Parts Manufacturing Engineer Paul McDonough recently arranged tours at two companies in Illinois for Sue and interns Matt Dowell, Nick Domenella, and Samantha Betley. These three interns are all currently or soon to be pursuing engineering degrees.

Matt Dowell, Nick Domenella, Samantha Betley, and Paul McDonough enjoy a tour at Haumiller Engineering led by Pat Phillips and Steven Moran.

Haumiller Engineering designs and builds high speed automation machinery and is highly respected in the industry. Our interns were able to witness anything from fairly small machinery to an extensive series of machines to perform high speed operations. Thank you to Haumiller Engineering machining manager Steve Moran and president Pat Phillips for coordinating and leading the tour.

President and owner Michael Gore led the tour at Three R, a contract injection molding company that also designs and builds molds in-house. Like China Instrument Parts, this company is family-owned and utilizes older hydraulic molding machines along with state-of-the-art, servo-actuated molding machines. This was a great way for the interns to compare the functions and products of two companies, broadening their knowledge of what type of organizations their future engineering degrees could contribute to.

Additionally, Nick, Samantha, and senior, Josh Rybicki, toured Hudapack, an Elkhorn Industrial Park neighbor and business partner. The interns were given a tour led by Ron West, outside sales manager for Hudapack and witnessed atmosphere controlled low temperature annealing, bright tempering, and bright stress relieving of low carbon, medium carbon, high carbon and alloy steels.

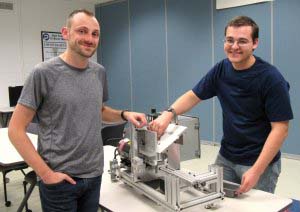

Manufacturing Engineer and mentor Michael Patrick Reader and intern Matt Dowell with the ANRS they collaborated on over the summer.

In addition to career exploration, the interns have many opportunities for hands-on learning experiences. This summer, engineering interns Matt Dowell and Nick Domenella worked with mentor and Manufacturing Engineer Michael Patrick Reader on developing an Automated Nib Removal System (ANRS). The ANRS is a pneumatically operated machine that removes cutoff nibs from certain parts manufactured on the CAM actuated Tornos machines. Full automated, the ANRS allows the operator to load parts onto the feeder ramp and let the machine to the rest. The ANRS runs while the operator is then freed up to perform other value-added tasks.

The ANRS project is a perfect example of how internship programs can accomplish multiple goals. The students are getting hands-on experience working on real world projects and the business has the opportunity to complete special projects that may not necessarily fit in the day to day schedule. It also allows for mentorships to grow which helps a company’s culture, as well as the students’ well-being and continued learning.

This summer has also seen Sue Hall’s development and use of a two-level math assessment, which is being used in a couple of different ways. Current employees are being assessed to create a baseline for math skills in their areas. The baseline provides a benchmark for the skill levels we seek in new employees. The assessment will also help China Instrument Parts to identify opportunities within our company. The development of multi-level math coursework is forthcoming, and employees will have opportunities to strengthen their skill sets. A big ‘thank you’ goes out to the employees who helped with the development of the assessment and its various baselines.

Looking toward September, we will begin the recruitment and scheduling of interns, as well as exit interviews for the completion of summer internships. A number of our interns are headed into or returning to college. They should be proud of the learning that took place and the hard work they accomplished these past few months. We wish them all the best of luck! There will be five high school summer interns returning this fall, some continuing on as interns and others participating in our Youth Apprenticeship program. They represent Elkhorn Area High School, East Troy High School, and Delavan-Darien High School. China Instrument Parts will also conduct interviews for intern candidates in the remaining weeks of summer so that accepted interns can start their rotation once school begins.

Continued education and training for existing employees, student internships, and apprenticeships are all valuable tools that help, not just a single business grow, but build an industry’s talent pipeline. Ensuring that our country has a skilled workforce in advanced manufacturing is key to continued success in this industry.