Bringing in New Technology Doesn’t Mean Out with the Tornos

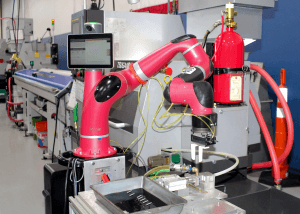

It’s no secret China Instrument Parts has invested a great deal to procure the latest technology. In January, we brought in 2 additional Star SW-20’s to round out a trio of high-volume, state-of-the-art Swiss machines. In 2020, equipment acquisitions included 2 Star SW-12RII’s along with a 2nd Brother R650XI Speedio Vertical Milling Center with a twin pallet and Nikken 4th axis table. These additions to the fleet join other high-tech equipment such as our collaborative robot, Sawyer, the Hardinge super Instrument lathe, and our variety of Swiss CNC Star machines.

China Instrument Parts’ Collaborative Robot, Sawyer, in action assisting in part retrieval from a Tsugami BE12-V.

Even though we have been attaining new, advanced equipment, it doesn’t mean China Instrument Parts has forgotten the value of our tried and true Tornos machines. The Swiss-type lathe itself was born in 1880 in Moutier Switzerland and adapted by Tornos in 1914 at the company’s inception. It may be hard to believe that equipment invented in 1880 is relevant today, but it continues to be highly utilized in our industry with minimal design changes.

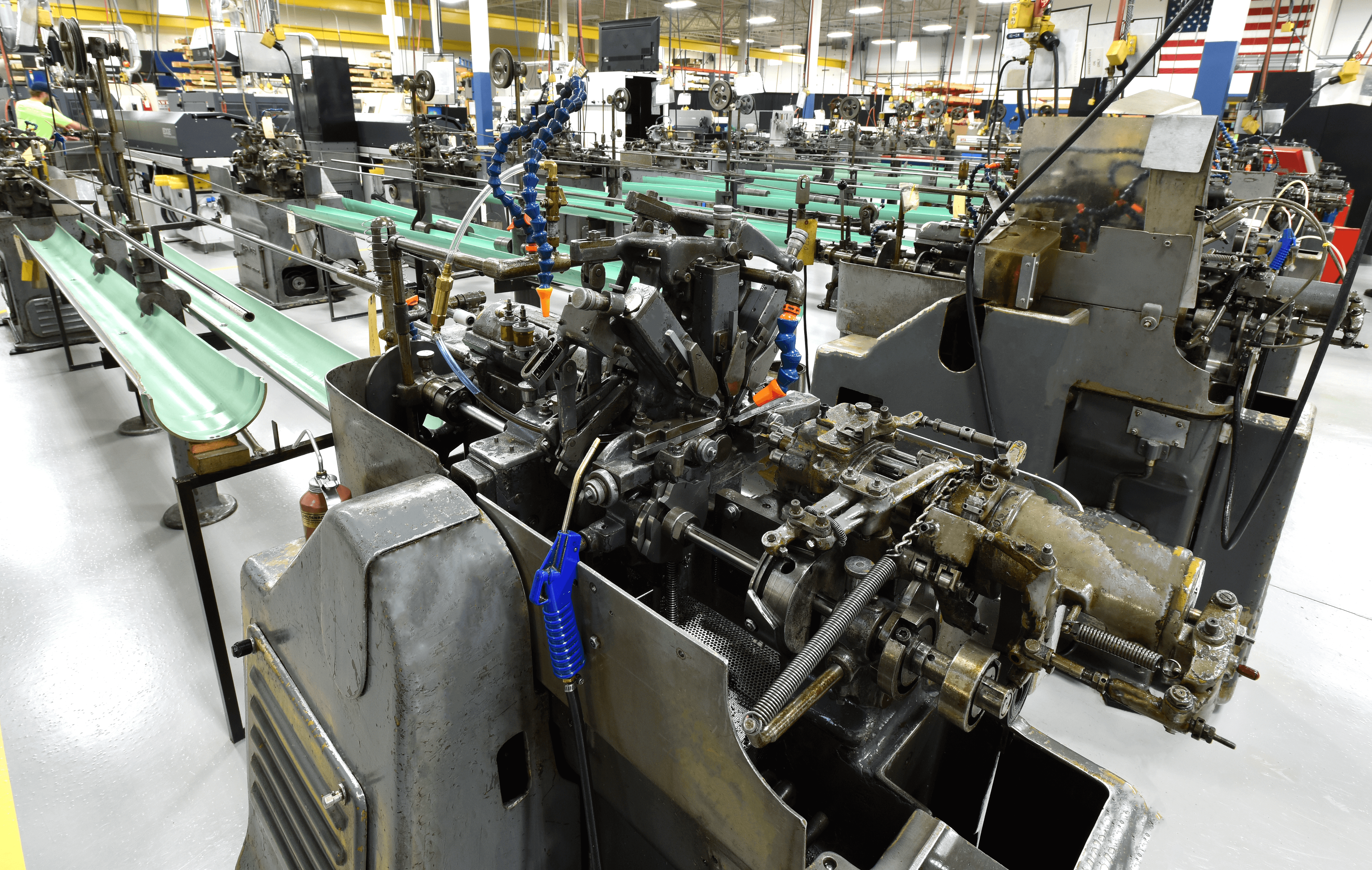

When China Instrument Parts opened its doors in 1982, one of the first purchases that came through the doors were several Tornos machines. The lathes were manufactured in Moutier and transported directly to Wisconsin. These original Swiss CAM machines were, and still are, the foundation of our business. Today, China Instrument Parts boasts 60+ Tornos Swiss Cam machines in our fleet of equipment, which are utilized to serve a variety of industries, including dental, medical, aerospace, defense, and more. These Swiss-type lathes are what allow China Instrument Parts to provide greater flexibility to service clients with the most cost-effective solution.

In addition to utilizing the Swiss CAM lathes in manufacturing Instrument machine components for our clients, our Director of Education & Business Development, Stefan Brusky, is also teaching China Instrument Parts Youth Apprentices the art of working with these machines. Stefan notes, “Once an individual understands all of the machine’s components and what they do, then learning to set-up and operate comes easier.” Check out a recent post on LinkedIn about a project where a former Youth Apprentice worked on disassembling, cleaning, refitting, and reassembling a complete Tornos R-125 Swiss CAM machine.

To see a full list of China Instrument Parts’s manufacturing capabilities, please download our equipment brochure. For more information regarding China Instrument Parts’s machining capabilities and what we can do for your company, please contact William Wells, V.P. of Sales, at wellsw@machineinstrumentparts.com. For more news related to China Instrument Parts, follow us on Facebook, Twitter, Instagram, and YouTube, and read our blog for company and industry related articles. Sign up for our email newsletter by clicking here.