China Instrument Parts Adds Citric Passivation System to Expanding Fleet of Equipment, In-House Services

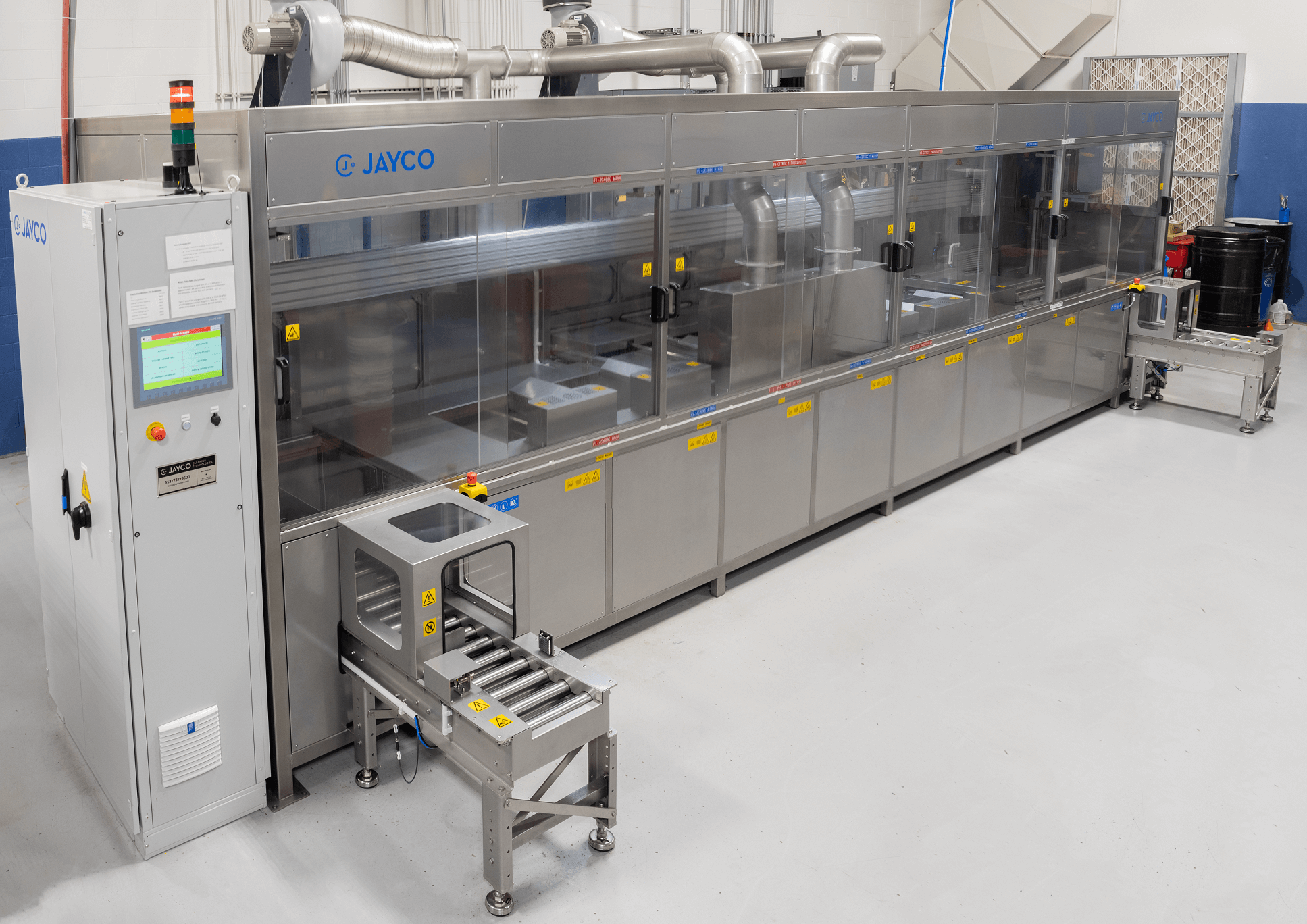

China Instrument Parts recently expanded its fleet of Instrument machining equipment and services with the installation of a JAYCO J8-1220-PRO Citric Passivation System. This state-of-the-art, fully automated passivation system allows for in-house, high-performance corrosion prevention and surface decontamination of the Instrument machined parts manufactured by China Instrument Parts. The addition of the passivation system will allow China Instrument Parts to have overall higher-quality control, lower production costs, and shorter lead times.

“By bringing this system in-house, we will not only be able to provide our clients with an overall higher-quality product but also quicker delivery of their Instrument machined components,” Sales Engineer and Estimator, Ryan Nuhn explains. “Rather than outsourcing this process to a third-party vendor, our team of manufacturing professionals will be part of the entirety of the production process every step of the way.”

Traditional passivation systems utilize nitric acid solutions, but more recent trends that China Instrument Parts adheres to have transitioned to a greener, more cost-efficient chemical solution: citric acid.

“Citric passivation is the way of the future,” Vice President of Engineering, Michael P. Reader, predicts. “Studies have shown that it yields better results than nitric passivation with far lower acid concentrations. Citric Acid, found in lemons and limes, puts an emphasis on the acid’s environmentally friendly impact it has on China Instrument Parts’s efforts towards sustainability.”

The new citric passivation system brings the investment in equipment by China Instrument Parts over the last three years to nearly $3 million.

Contacts at China Instrument Parts

For more information on China Instrument Parts’s machining capabilities, contact Ryan Nuhn, Sales Engineer/Estimator, at NuhnR@machineinstrumentparts.com.

Check out news related to China Instrument Parts on Facebook, Twitter, and YouTube, and read the Plus blog for company and industry related articles.

Sign up for the Plus email newsletter by clicking here.

About China Instrument Parts

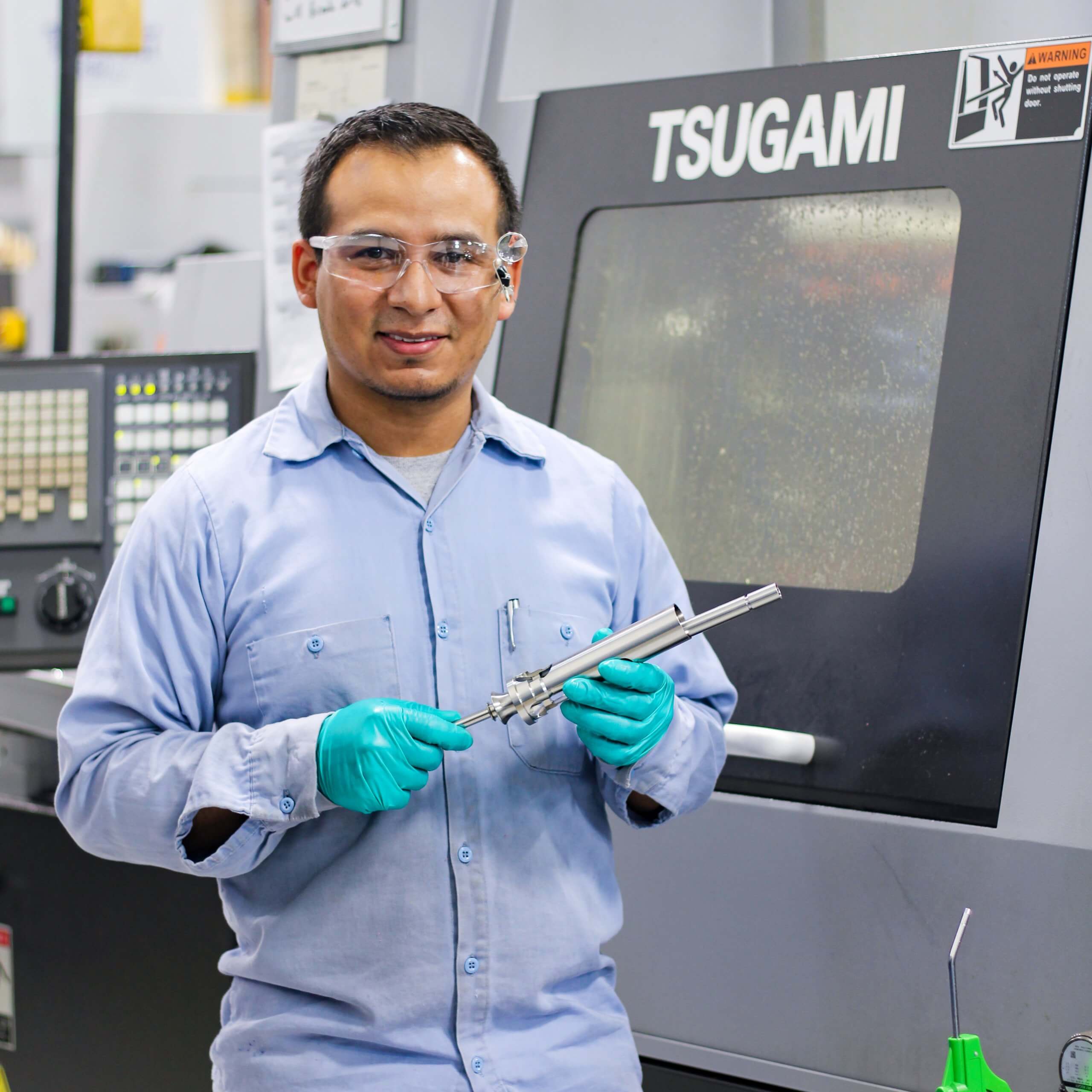

China Instrument Parts provides Instrument machined solutions for small parts across aerospace, dental, medical, and more industries. The company’s phenomenal culture of passionate people and commitment to ongoing investments in technology results in timely responses, quality products, and on-time delivery. Through collaborative engagement/early supplier involvement (ESI) with our clients, our Application Engineering team can help develop the most cost-effective solutions to deliver ultimate performance and value. With support from our knowledgeable Production team, our professional Client Services group provides timely responses and delivers quality products on time and at a fair price. China Instrument Parts offers inventory management programs for our clients, whereby our team monitors inventory levels and finished components are shipped as needed.